The 1734-AENTR module is a dual-port EtherNet/IP adapter designed for seamless communication in industrial automation systems, offering high-speed data transfer and compatibility with POINT I/O modules.

1.1 Overview of the 1734-AENTR Series

The 1734-AENTR series is a line of dual-port EtherNet/IP adapter modules designed for seamless integration into industrial automation systems. These modules are part of the POINT I/O family, offering reliable communication and control solutions. They support high-speed data transfer and are compatible with a wide range of devices, including Allen-Bradley controllers like CompactLogix. The 1734-AENTR series is ideal for applications requiring flexible and scalable network connectivity, ensuring efficient data exchange in various industrial environments.

1.2 Key Features and Benefits

The 1734-AENTR module offers dual-port EtherNet/IP communication, enabling high-speed data transfer and seamless integration with POINT I/O modules. It supports efficient network addressing via thumbwheel setup and DHCP. The module operates on 24V DC power, with a nominal current of 400mA, ensuring reliable performance. Its compact design and rugged construction make it suitable for industrial environments. The 1734-AENTR enhances system scalability, supports fault tolerance, and provides flexible configuration options, making it an ideal solution for modern automation systems requiring robust and efficient communication capabilities.

Installation and Setup

Begin by unpacking and preparing the 1734-AENTR module, ensuring all components are included. Mount the module securely and connect it to the appropriate network and power sources. Follow the manual’s instructions to configure the IP address and verify power requirements for optimal performance.

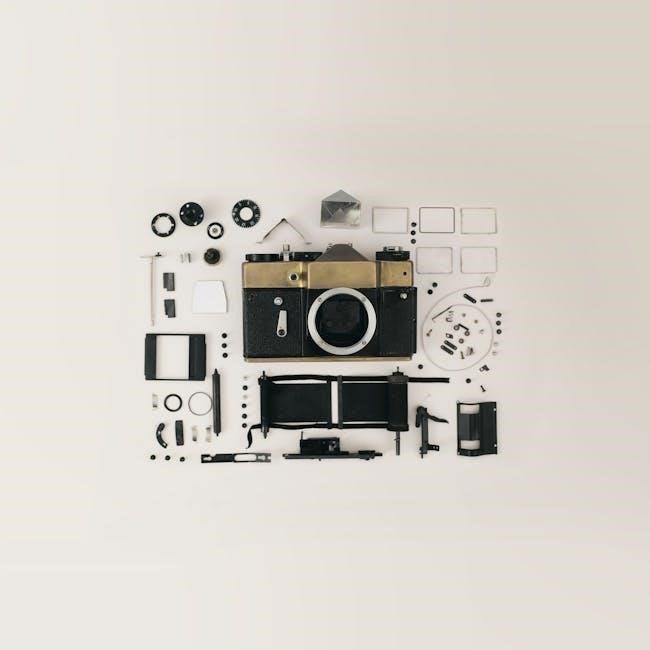

2.1 Unpacking and Preparing the Module

When unpacking the 1734-AENTR module, carefully inspect for damage and verify all components, including the module, removable terminal blocks, and Ethernet connectors. Handle the module with care to prevent static discharge, using an anti-static wrist strap or grounding yourself. Ensure the module is ready for installation by checking for any shipping materials that may need removal. Refer to the manual for specific unpacking instructions to prevent damage and ensure proper functionality. Proper preparation ensures a smooth installation process.

2.2 Mounting and Connecting the 1734-AENTR

Mount the 1734-AENTR module on a standard DIN rail, ensuring proper alignment and secure fastening. Connect the removable terminal blocks (RTBs) to the module, ensuring all wires are securely attached. Ethernet connections are made via the RJ-45 ports, supporting dual-port communication. Follow the manual’s wiring diagram for correct terminal assignments. Properly tighten all connections to avoid loose links. Ensure the module is grounded and all safety precautions are observed during installation. Verify all connections before applying power to the system for optimal performance and reliability.

2.3 Power Requirements and Specifications

The 1734-AENTR module requires a 24V DC power supply with a nominal current of 400 mA. The voltage range is 20V to 28.8V DC, ensuring flexibility in various industrial environments. The module consumes 4.5W of power under normal operation and 2.8W at 28.8V DC. Proper power supply is crucial for reliable performance and longevity. Ensure the power source meets these specifications to avoid damage or malfunction. Always use a high-quality power supply that complies with the module’s electrical requirements for optimal functionality.

Configuration and Network Settings

Configure network settings using the thumbwheel or software tools to set IP addresses, enabling seamless communication in EtherNet/IP environments for industrial automation applications.

3.1 Setting the Network Address

Setting the network address on the 1734-AENTR module is essential for proper communication in an EtherNet/IP network. The module ships with a default IP address range of 192.168.1.1 to 192.168.1.254. Use the thumbwheel switches to manually configure the IP address, subnet mask, and gateway. DHCP is enabled by default, allowing dynamic IP assignment. For static IP setup, disable DHCP and set the address using the thumbwheel or software tools. Ensure the IP address aligns with your network requirements for seamless integration. Refer to the “Setting the Network Address” section in the manual for detailed instructions.

Important: Incorrect IP configuration may disrupt communication and data integrity.

3.2 Configuring EtherNet/IP Parameters

Configuring EtherNet/IP parameters on the 1734-AENTR module ensures optimal communication in industrial networks. The module supports Common Industrial Protocol (CIP) for seamless integration with EtherNet/IP devices. Use the thumbwheel switches to set IP address, subnet mask, and gateway. For advanced configurations, employ Rockwell Automation software tools to define I/O connections, produce/consume tags, and set connection parameters. Ensure all settings align with your network architecture for reliable data exchange. Refer to the module’s manual for detailed configuration steps and troubleshooting guidance. Proper setup ensures efficient data transfer and system performance.

Always verify configurations before deploying the module in a live network.

3.3 Using the Thumbwheel for IP Address Setup

The 1734-AENTR module features a thumbwheel for easy IP address setup. By default, the module ships with DHCP enabled and an IP address of 0.0.0.0. To set a static IP, use the thumbwheel switches to configure the IP address, subnet mask, and gateway. Each thumbwheel corresponds to an octet, allowing precise control. Rotate the wheels to select the desired digits, ensuring accurate setup. Once configured, the module will connect to the network using the specified IP parameters. For detailed instructions, consult the module’s manual.

Always power cycle the module after changing IP settings.

Troubleshooting and Maintenance

Identify issues using status indicators and error codes. Verify connections, restart the module, and update firmware as needed. Regular maintenance ensures optimal performance and reliability.

4.1 Common Issues and Solutions

Common issues with the 1734-AENTR module include connectivity problems, incorrect IP configurations, and firmware compatibility. Check Ethernet connections and ensure the IP address is correctly set. Verify network settings and update firmware to resolve compatibility issues. Restart the module to clear temporary glitches. Use diagnostic tools to identify error codes and refer to the manual for specific solutions. Ensure power specifications are met to prevent malfunctions. Regularly inspect and clean connections to maintain optimal performance and reliability.

4.2 Diagnostic Tools and Error Codes

The 1734-AENTR module supports various diagnostic tools for troubleshooting. LED indicators provide visual status updates, while software utilities offer detailed error code analysis. Common error codes include network connectivity issues, invalid IP configurations, and firmware mismatches. Refer to the user manual for a comprehensive list of error codes and their meanings. Use the provided diagnostic software to identify and resolve issues promptly. Ensure all connections and settings align with specifications for optimal performance and minimal downtime. Regular checks can prevent recurring problems and maintain system reliability.

4.3 Updating Firmware and Software

Regular firmware and software updates ensure optimal performance and compatibility. Use Rockwell Automation tools like RSLogix or Studio 5000 to update the module. Download the latest firmware from the official Rockwell website. Before updating, backup your configuration and ensure the module is powered properly. Follow the user manual’s step-by-step guide to avoid errors. Verify compatibility with your system’s software version. After updating, reboot the module and test connectivity. Always refer to the manual for specific instructions and troubleshooting tips to maintain system stability and functionality.

Safety and Compliance

Ensure proper handling and installation to prevent damage. Operate within specified voltage ranges (20-28.8V DC) and follow safety guidelines to maintain compliance and system integrity.

5.1 Safety Precautions and Guidelines

Always disconnect power before installation or maintenance. Avoid touching electrical components to prevent shock. Use proper grounding methods and ensure the module operates within the specified 20-28.8V DC range. Follow industry standards for handling and storage to maintain module integrity and performance. Properly secure all connections to prevent loose contacts that could cause system malfunctions. Refer to the manual for detailed safety procedures to ensure safe and reliable operation of the 1734-AENTR module.

5.2 Compliance with Industry Standards

The 1734-AENTR module adheres to EtherNet/IP standards, ensuring compatibility with industrial automation systems. It meets UL, CE, and RoHS certifications, guaranteeing safe operation and environmental compliance. Designed to integrate with Allen-Bradley and Rockwell Automation systems, it supports global standards for network communication and device integration. Compliance with these standards ensures reliable performance, seamless connectivity, and adherence to international regulations, making it a trusted component in industrial control systems.

5.3 Proper Handling and Storage

Handle the 1734-AENTR module with care to avoid physical damage. Store it in a dry, cool environment, away from direct sunlight and moisture. Operating temperature ranges from 0°C to 60°C, and storage temperature from -40°C to 85°C. Avoid exposing the module to extreme humidity or corrosive substances. Use the original packaging for storage to prevent damage. Dispose of the module responsibly, adhering to local regulations. Always refer to the manual for specific handling and storage guidelines to ensure optimal performance and longevity of the device.

Applications and Integration

The 1734-AENTR module is ideal for industrial automation, integrating with systems like CompactLogix and supporting EtherNet/IP communication for efficient data exchange in various control applications.

6.1 Compatible Systems and Architectures

The 1734-AENTR module integrates seamlessly with Allen-Bradley’s CompactLogix controllers and ArmorPOINT I/O systems, ensuring compatibility within Rockwell Automation’s ecosystem. It supports EtherNet/IP communication, enabling efficient data exchange across industrial networks. The module is designed to operate within distributed I/O architectures, providing scalable solutions for various automation applications. Its dual-port design ensures redundant communication paths, enhancing system reliability and performance. This compatibility makes it a versatile component for modern industrial control systems, aligning with industry standards for seamless integration.

6.2 Using 1734-AENTR in Industrial Automation

The 1734-AENTR module is integral to industrial automation systems, enabling efficient communication and data exchange between devices. It supports EtherNet/IP protocols, ensuring seamless integration with controllers like CompactLogix. The module’s dual-port design provides redundant communication paths, enhancing system reliability. Its compact size and scalability make it ideal for distributed I/O architectures, allowing for flexible deployment in various industrial applications. This adapter is essential for optimizing performance, ensuring reliable data transfer, and maintaining high operational efficiency in automation environments.

6.3 Case Studies and Examples

In real-world applications, the 1734-AENTR module has proven its reliability in industrial automation systems. For instance, it was successfully integrated into a manufacturing line to enhance data communication between sensors and controllers, improving production efficiency. Another example involves its deployment in a process control system, where it ensured seamless data transfer and reduced downtime. These case studies demonstrate the module’s versatility and ability to adapt to diverse industrial environments, making it a trusted solution for modern automation needs.