The Continental O-200 Parts Manual provides essential information for maintaining and overhauling the O-200 engine‚ covering models C75‚ C85‚ C90‚ and O-200. It includes a comprehensive numerical parts list‚ detailed diagrams‚ and specifications‚ serving as a vital resource for mechanics and operators to ensure proper engine maintenance and performance.

1.1 Overview of the Continental O-200 Engine

The Continental O-200 engine is a four-cylinder‚ air-cooled‚ horizontally opposed aircraft engine. It is widely used in light aircraft for its reliability and fuel efficiency. With a displacement of 201 cubic inches‚ it produces 100 horsepower at 2‚800 rpm. Known for its simple design‚ the O-200 is popular in aircraft like the Cessna 150 and other small general aviation planes. Its compact size and durability make it ideal for training and recreational flying. The engine features a direct-drive propeller system and a carbureted fuel injection. Regular maintenance‚ as outlined in the parts manual‚ ensures optimal performance and longevity.

1.2 Purpose and Structure of the Parts Manual

The Continental O-200 Parts Manual is designed to assist mechanics and operators in maintaining‚ repairing‚ and overhauling the engine. It provides a detailed numerical parts list‚ diagrams‚ and specifications for accurate identification and ordering of components. Organized into sections such as engine models‚ parts identification‚ and usage of the Illustrated Parts Catalog (IPC) tool‚ the manual ensures efficient navigation. Its loose-leaf format allows for updates‚ making it a dynamic resource for professionals. The manual is indispensable for ensuring compliance with Continental Motors’ standards and maintaining engine performance and safety.

Continental O-200 Illustrated Parts Catalog

The Continental O-200 Illustrated Parts Catalog serves as a detailed reference for identifying and ordering engine components. It provides numerical and visual listings for efficient part identification.

2.1 Numerical Parts List and Identification

The Continental O-200 Illustrated Parts Catalog features a detailed numerical parts list‚ assigning each component a unique identifier for precise identification. This system streamlines the process of locating and ordering parts‚ ensuring accuracy and efficiency. The catalog covers various engine models‚ including the C75‚ C85‚ C90‚ and O-200 series‚ providing a comprehensive reference for mechanics and operators. By organizing parts numerically‚ the catalog minimizes errors and facilitates quick access to essential components‚ making it an indispensable tool for maintenance and overhaul activities.

2.2 Engine Models Covered in the Catalog

The Continental O-200 Illustrated Parts Catalog covers a range of engine models‚ including the C75‚ C85‚ C90‚ and O-200 series. It also includes variants such as the O-200-A and O-200-B‚ ensuring comprehensive coverage for different configurations. The catalog is structured to apply to all listed engine models‚ providing a single reference for parts identification and ordering. This inclusive approach simplifies maintenance and overhaul processes‚ making it a valuable resource for operators and mechanics working with these engine types.

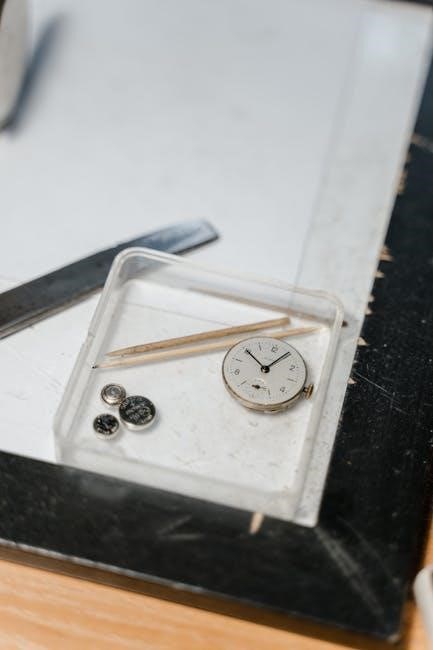

2.3 How to Use the Illustrated Parts Catalog (IPC) Tool

The Illustrated Parts Catalog (IPC) tool provides an organized interface for identifying and ordering parts for the Continental O-200 engine. Users can navigate through bookmarked sections or search for specific components using part numbers or descriptions. The tool includes detailed diagrams and lists‚ allowing users to locate parts efficiently. For technical support‚ users should have their engine serial number and model specification ready when contacting Continental Motors. This tool streamlines the parts identification process‚ ensuring accuracy and convenience for mechanics and operators.

Maintenance and Overhaul Parts Replacement

This section outlines essential parts replacement procedures for maintaining and overhauling the Continental O-200 engine‚ ensuring optimal performance and longevity through proper maintenance practices.

3.1 Mandatory Overhaul Replacement Parts

The Continental O-200 engine requires specific parts to be replaced during overhaul to ensure reliability and performance. These include gaskets‚ seals‚ bearings‚ and valves‚ which are critical for preventing leaks and maintaining compression. The Major Overhaul Gasket Set is essential‚ containing intake hoses and other vital components. Additionally‚ pistons‚ cylinders‚ and connecting rods may need replacement if worn beyond acceptable limits; Always refer to the official parts catalog for a detailed list of mandatory replacement items to guarantee compliance with manufacturer standards and ensure safe operation. Proper replacement of these parts is crucial for extending engine lifespan.

3.2 Gasket Maker Application and Crush Washer Installation

Proper application of gasket makers and crush washers is critical for ensuring leak-free connections in the Continental O-200 engine. Gasket makers‚ such as silicone-based sealants‚ are applied to surfaces like intake manifolds and oil pans to create a durable seal. Crush washers are installed on specific bolts‚ such as cylinder head or oil sump bolts‚ to ensure proper torque and sealing. Both components must be replaced during overhaul to maintain engine integrity and prevent fluid leaks. Always follow torque specifications for bolts using crush washers to avoid over-tightening or under-tightening‚ which can compromise the seal. This step is vital for ensuring reliable engine performance and longevity.

3.3 Component-Specific Torque Specifications

The Continental O-200 engine requires precise torque values for various components to ensure proper assembly and prevent damage. Critical areas include cylinder head bolts‚ intake manifold studs‚ and oil pan fasteners. Torque specifications are detailed in the parts manual‚ with specific values provided for each component. For example‚ cylinder head bolts typically require 18-20 ft-lbs of torque‚ while intake manifold studs may need 10-12 ft-lbs. Adhering to these guidelines is essential to maintain engine integrity and prevent leaks or premature wear. Always refer to the manual for exact specifications during maintenance or overhaul.

Troubleshooting Common Issues

The Continental O-200 parts manual assists in identifying and resolving common engine issues‚ such as worn or damaged components‚ through detailed diagnostic procedures and repair guidance. This section helps mechanics efficiently troubleshoot problems‚ ensuring timely and accurate solutions to maintain optimal engine performance and safety. Regular inspection of parts and adherence to maintenance schedules are emphasized to prevent recurring issues. By following the manual’s guidelines‚ operators can address challenges effectively‚ minimizing downtime and extending engine lifespan. Proper troubleshooting ensures reliable operation and compliance with safety standards.

4.1 Identifying and Replacing Worn or Damaged Parts

The Continental O-200 parts manual provides detailed guidance for identifying worn or damaged components‚ ensuring precise replacement procedures. It outlines a systematic approach to inspecting engine parts‚ such as gaskets‚ bearings‚ and pistons‚ using the numerical parts list and IPC tool for accurate identification. The manual emphasizes proper installation techniques and torque specifications to prevent further damage. Regular inspection and timely replacement of worn parts are crucial for maintaining engine performance‚ safety‚ and reliability. Adhering to these guidelines ensures compliance with manufacturer standards and extends the engine’s operational lifespan.

4.2 Common Problems and Solutions in the O-200 Engine

The Continental O-200 engine may experience issues such as oil leaks‚ low compression‚ or excessive vibration. Oil leaks often stem from worn gaskets or seals‚ which can be resolved by replacing them with genuine parts. Low compression may indicate cylinder damage or faulty valves‚ requiring inspection and replacement. Excessive vibration could result from propeller imbalance or misaligned engine mounts‚ which should be adjusted or replaced. Regular maintenance and adherence to the parts manual’s guidelines help mitigate these issues‚ ensuring optimal engine performance and longevity.

Technical Specifications and Dimensions

The Continental O-200 engine has a dry weight of approximately 225 pounds and produces 100 horsepower at 2750 RPM. Its displacement is 201 cubic inches‚ designed for efficiency and reliability. Dimensional drawings in the manual ensure accurate measurements for installation and maintenance‚ adhering to Continental Motors’ rigorous standards.

5.1 Key Specifications of the Continental O-200 Engine

The Continental O-200 engine is a four-cylinder‚ air-cooled‚ horizontally opposed aircraft engine producing 100 horsepower at 2‚750 RPM. Its displacement is 201 cubic inches‚ with a compression ratio of 7.0:1. The engine features a dry weight of approximately 225 pounds‚ making it lightweight and efficient for small aircraft. It utilizes a magneto ignition system and is designed for reliable performance in general aviation applications. Fuel capacity and oil system specifications are detailed to ensure proper maintenance and operation;

5;2 Dimensional Drawings for Engine Components

The Continental O-200 engine components are detailed in precise dimensional drawings‚ ensuring accurate measurements for maintenance and repairs. These drawings‚ found in the Illustrated Parts Catalog (IPC)‚ provide critical data for engine assembly‚ disassembly‚ and custom installations. Key components like cylinders‚ crankcases‚ and valve systems are meticulously illustrated‚ highlighting mounting points‚ flanges‚ and bolt patterns. The IPC tool allows users to search and navigate these drawings efficiently‚ making it an invaluable resource for mechanics and technicians working on the O-200 engine.

Supporting Documentation and Resources

The Continental O-200 Parts Manual is supported by service bulletins‚ technical support contacts‚ and additional maintenance manuals‚ ensuring comprehensive guidance for engine maintenance and repair operations.

6.1 Service Bulletins and Technical Support Contacts

Service bulletins provide critical updates and modifications for the Continental O-200 engine‚ ensuring compliance with safety and performance standards. Technical support contacts are available to address troubleshooting and maintenance inquiries. Users can access service bulletins through authorized Continental Motors distributors or customer service. For assistance‚ operators should have their engine serial number‚ model‚ and specifications ready. Regularly updated bulletins ensure adherence to the latest engineering advancements and regulatory requirements‚ supporting optimal engine operation and longevity.

6.2 Additional Maintenance and Overhaul Manuals

Supplementing the parts manual‚ Continental Motors offers additional maintenance and overhaul manuals tailored for the O-200 engine. These resources provide detailed procedures for troubleshooting‚ engine disassembly‚ and reassembly. Operators can access these manuals through authorized distributors or customer service. They include torque specifications‚ part replacement guidelines‚ and best practices for extending engine life. These manuals are essential for ensuring compliance with manufacturer recommendations and maintaining optimal engine performance and safety. Regular updates are issued to reflect the latest technical advancements and service protocols.

Best Practices for Ordering Parts

Always verify part numbers and supersedure history with authorized Continental Motors distributors to ensure accurate orders and compatibility with your O-200 engine model.

7.1 How to Check Part Number Supersedure History

Verifying part number supersedure history is crucial for ensuring compatibility and compliance with the latest specifications. Use the Illustrated Parts Catalog (IPC) tool or contact an authorized Continental Motors distributor to confirm current part numbers. Refer to service bulletins and technical support resources for updates. Always cross-check the engine model and serial number to avoid mismatches. This process ensures that obsolete or updated parts are accurately identified and replaced‚ maintaining the integrity and performance of the O-200 engine during maintenance or overhaul.

7.2 Contacting Authorized Continental Motors Distributors

For accurate parts identification and ordering‚ contact authorized Continental Motors distributors. They provide genuine parts‚ technical advice‚ and warranty support. Ensure to have your engine model‚ serial number‚ and specifications ready for efficient assistance. Distributors can verify part number supersedure history and ensure compliance with the latest service bulletins. This direct communication guarantees the correct parts are supplied‚ maintaining engine performance and safety. Visit the Continental Motors website or refer to the parts manual for a list of authorized distributors and contact information.